Our Guiding Principles

Advancing Tradition – Safe. Efficient. Collaborative.

As an independent, family-owned company and a leading competence partner, we have shaped the way of safe and efficient gaseous and fluid handling. Worldwide. For generations. We are driven by a commitment to long-term value creation, technical excellence, and responsible action. Our operations and strategic direction are guided by the following core principles:

Independence: We secure our independence through sustainable organic growth, without reliance on external investors.

Continuity: We build on a long-term perspective, ensuring the transfer of ownership to the next generation.

Innovation: We continuously invest in research and development to offer customers innovative solutions.

Customer Orientation: We understand customer needs and provide tailored, high-quality system solutions.

Global Presence: We are consistently expanding our global presence, entering new markets to drive growth.

Expansion: We grow both organically and through necessary strategic acquisitions.

Prudence & Discretion: We operate with careful consideration and restraint, avoiding excessive emphasis on our market dominance.

These principles form the cornerstone of our identity, guiding our daily actions and our interactions with customers, employees, and partners as we build a sustainable future together.

The ELAFLEX Group

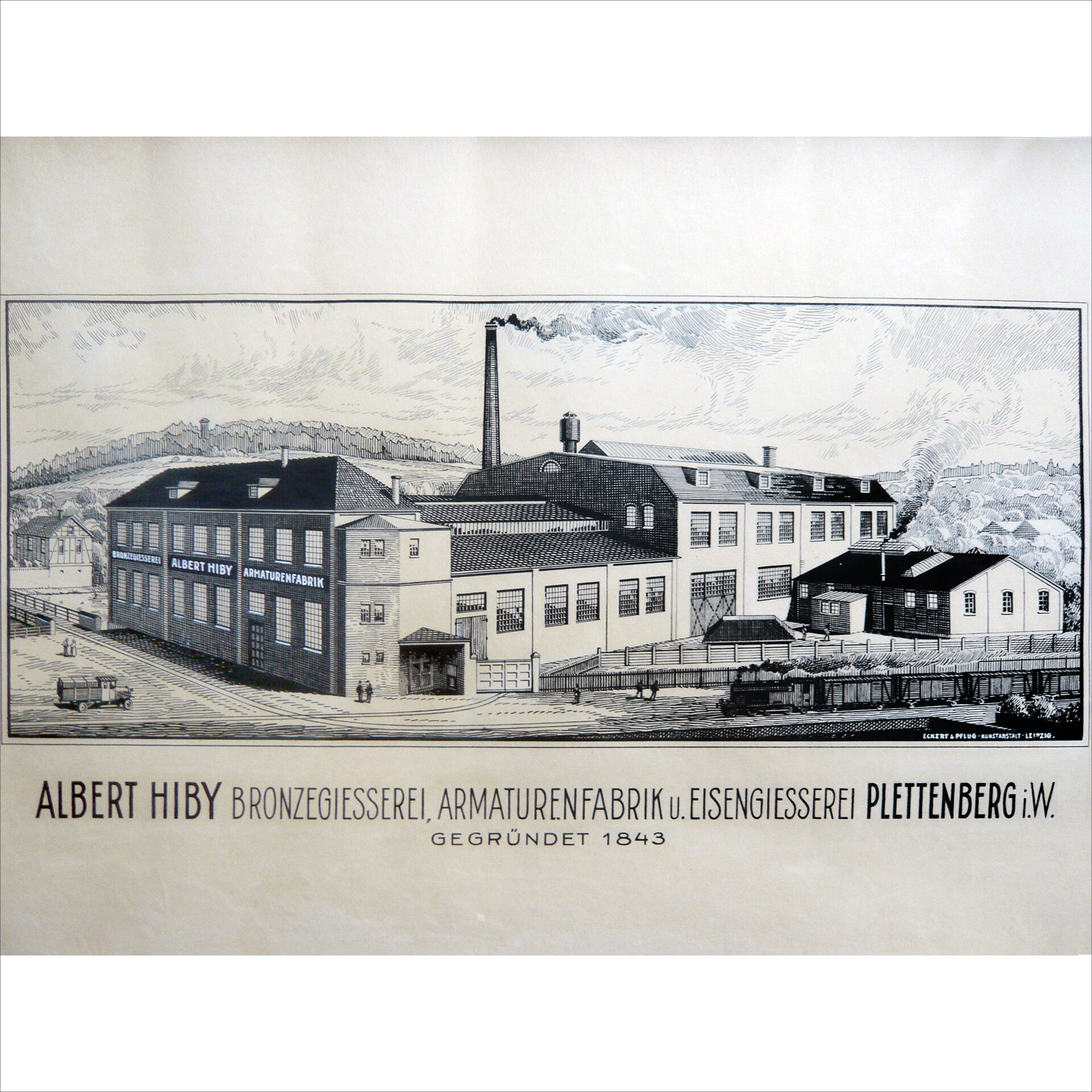

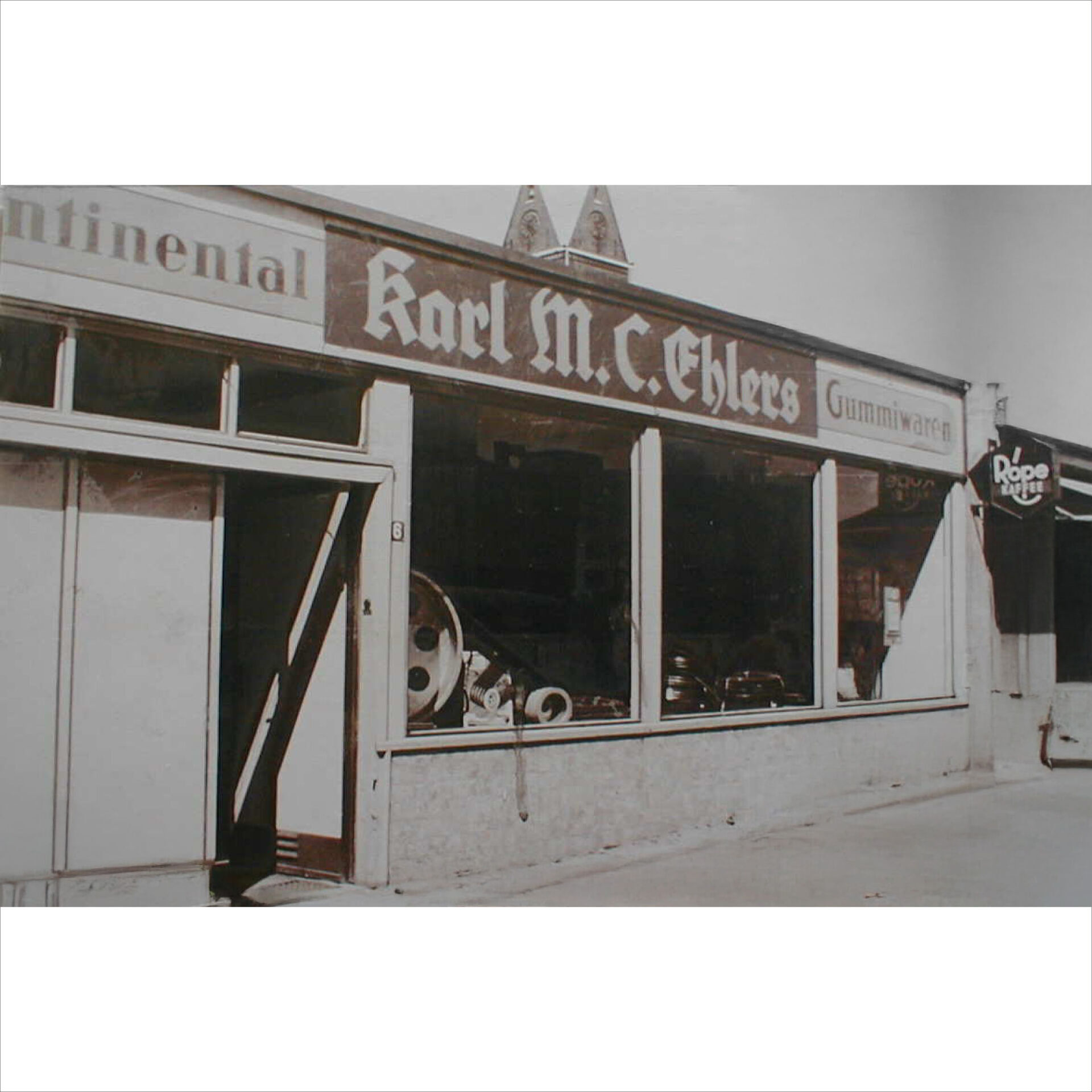

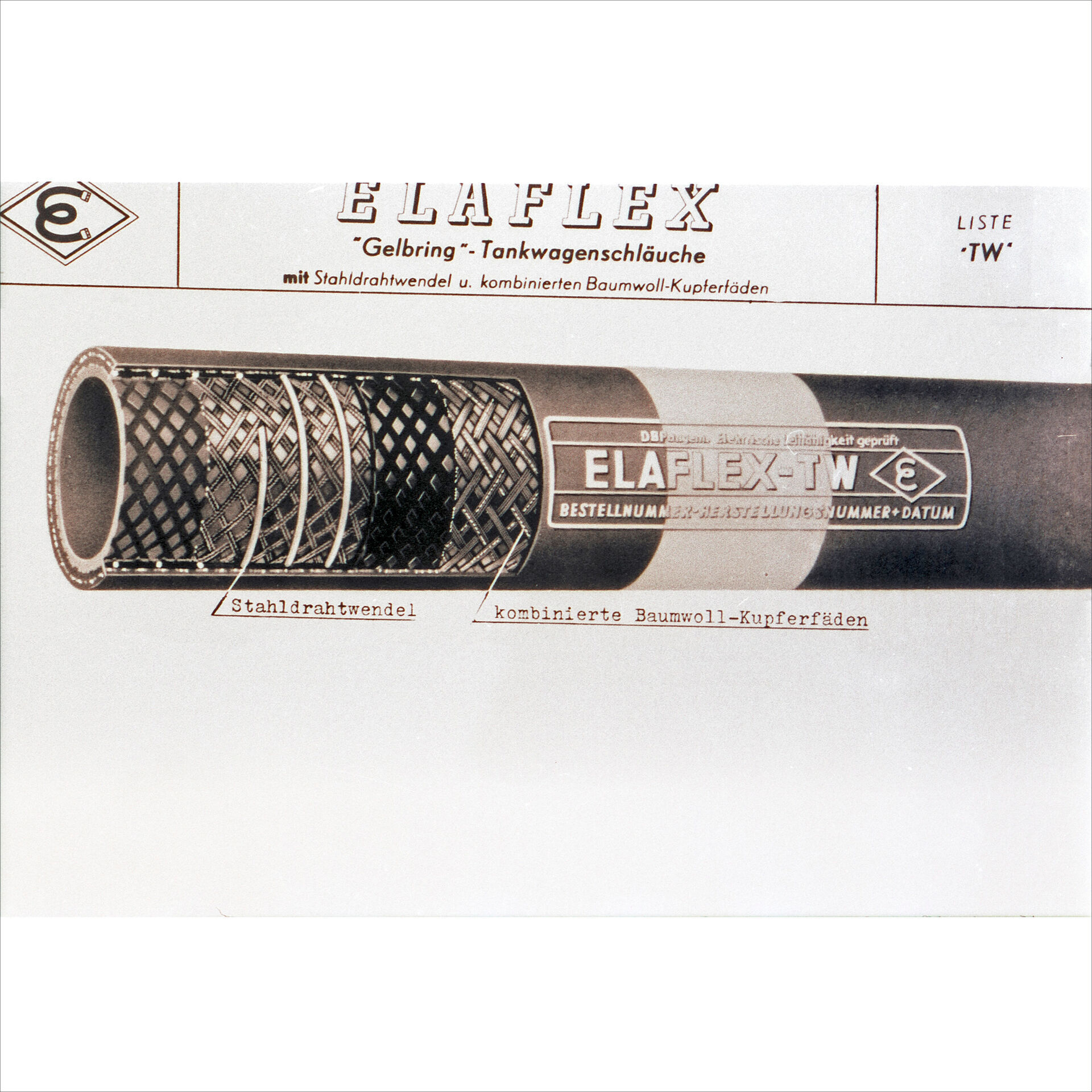

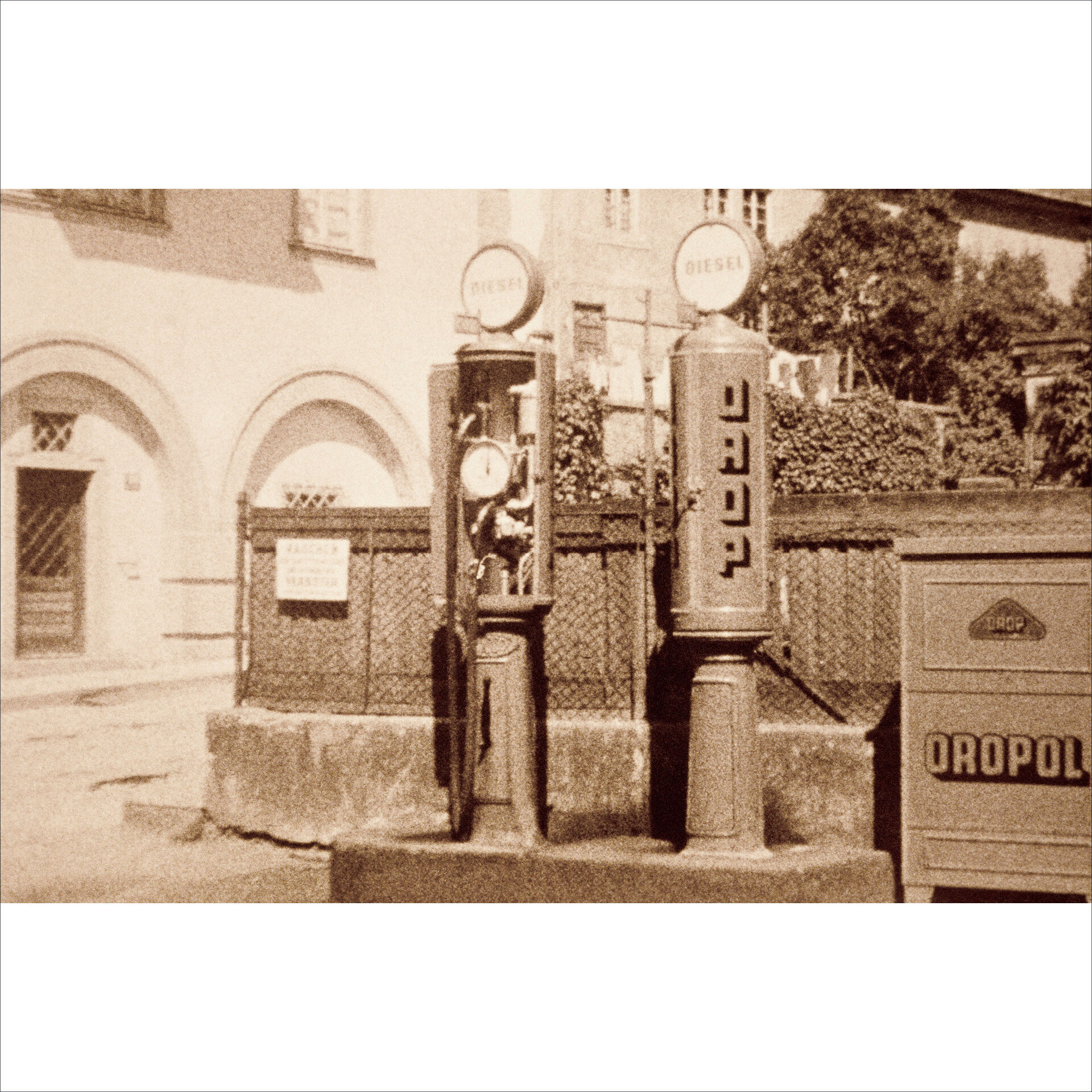

More than a Century of Innovation and Strategic Growth in Handling of Gases and Fluids

Join the journey through time, tracing the remarkable evolution of the ELAFLEX Group. From humble beginnings in the early 20th century to our present-day position as a global leader in refuelling technology, discover the key milestones, groundbreaking innovations, and strategic partnerships that have shaped our century-long legacy.

Acquisitions and Stakes

Setting Industry Standards

Our Company values

Our values define who we are. They shape the way we think, act, and grow –

driving innovation, ensuring quality, and building trusted relationships that stand the test of time.